our technology

Learn about the innovative features and details of the barge

Simple and yet advanced

The design of the Flexible Filtering Environmental Barge, FEB-I, is simple, yet complex, as the barge contains a wide range of features that make it unique and capable of offering innovative solutions for oil spill response and costal protection.

Explore how the filtering works

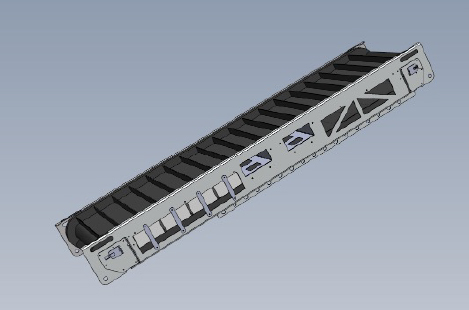

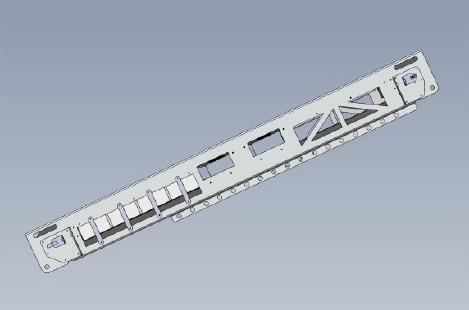

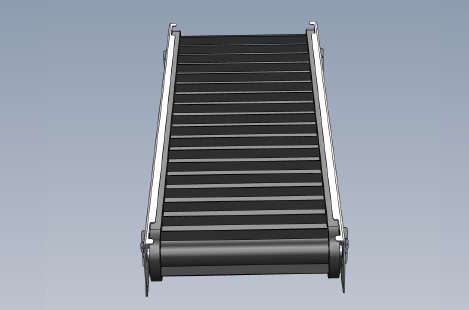

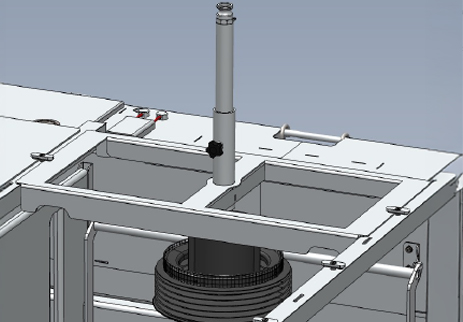

The FLEX-FEB oil skimmer

All commercially available oil skimmers and associated pumps are hydraulic or diesel-hydraulic driven (except for a few low-capacity skimmers). These work quite well but require constant monitoring and the presence of a hydraulic mechanic in case of breakdown.

FLEX-FEB has therefore developed an electrically driven belt skimmer, which is very simple to operate, does not require continuous monitoring and maintenance, and which can even be remotely controlled. With the on-board battery pack and solar panels, the belt skimmer can operate continuously and autonomously for several days.

The belt skimmer also has the advantage that it can be used to collect other types of surface waste, such as seaweed, eelgrass and plastic, etc. However, this requires that the belt be replaced with another one that is optimized for collecting solid waste.

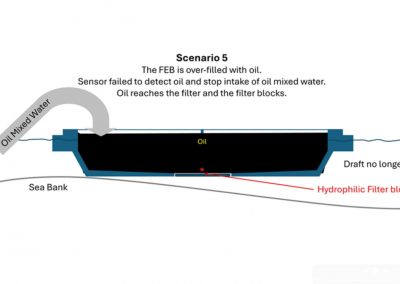

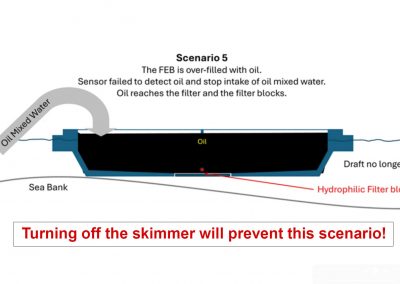

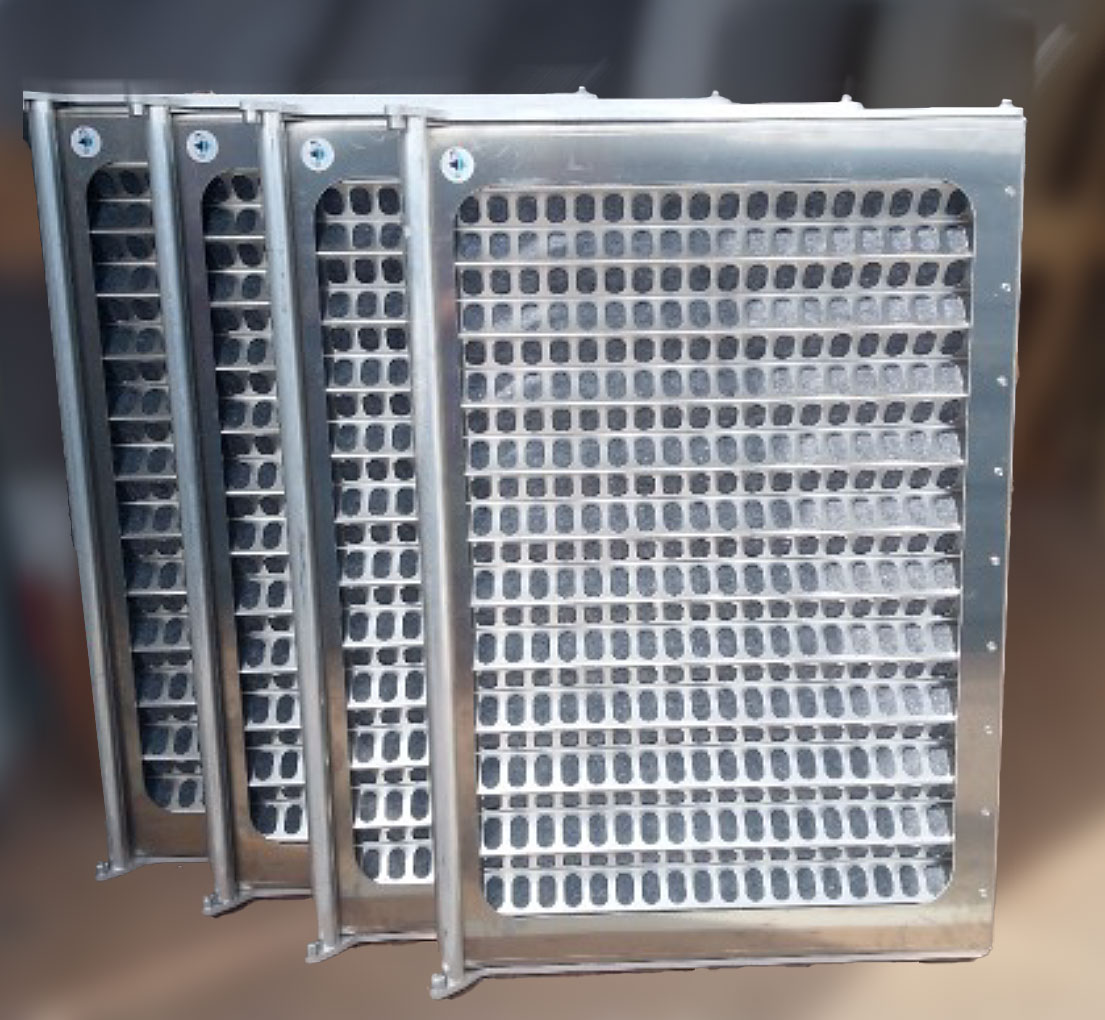

The FEB-filter

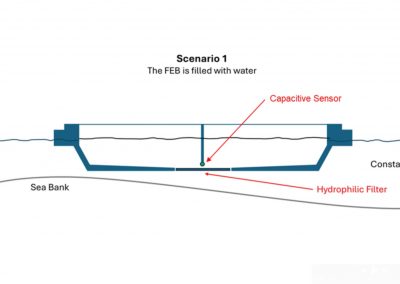

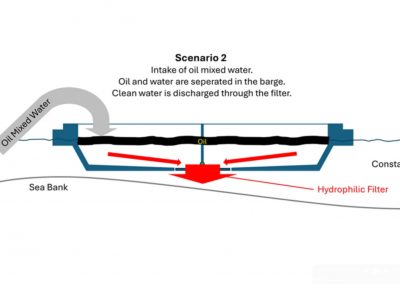

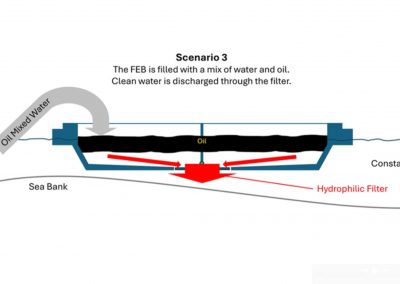

The FEB-I is equipped with a special hydrophilic and lipophobic filter that prevents oil-contaminated water from running back into the surrounding water. The filter is built into a specially designed filter cartridge that enables replacement of the filter during operation.

Used/expired filter cartridges may be returned to FLEX-FEB for exchange for cartridges with new filters.

Operating the FEB

FEB-I units can be operated actively by towing them in the oil booms to circumnavigate and contain the oil slick, or passively by anchoring the FEB-I units in the oil booms attached to the FEB-I or behind a long oil boom. The oil is always collected from the leeward side of the oil slick, but as wind and currents are constantly changing, this is a dynamic scenario.

It is obviously up to the owner/operator of the FEB-I units how they will be operated, depending on the operator’s operational concept and the actual scenario.

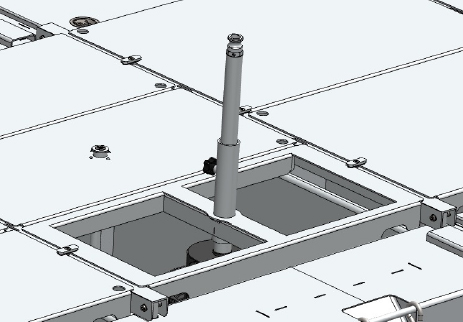

Connecting oil booms to the FEB

The FEB can be connected to oil booms using specially designed “mounting rods”, which allow the barge and the oil boom to move independently of each other in the water.

When The FEB is connected to oil booms, the booms can be used to tow the FEB towards an oil slick, or anchor the FEB in front of the oil slick, thereby encircling the oil slick, which can be skimmed into the FEB.

Monitoring and Control Systems

The core functionality of FEB-I is the unique on-site filtration capability – either as a stand-alone capability or as a “capacity extender” for existing oil collecting equipment.

In addition, FEB-I can operate autonomously, without 24-7 manning, thereby achieving greater endurance than conventional oil recovery equipment. The autonomous operation is supported by the monitoring and control systems that can be mounted on FEB-I as optional equipment:

Optional equipment

GPS and AIS

GPS and AIS enable other vessels to track the barge, and enable operators to locate and monitor the barge’s exact position.

Nav light

The navigation light (360o white light) for visual spotting of the FEB-I may be turned on and off remotely .

Camera

A GSM camera enables remote monitoring of the operation and the surroundings of the barge.

Remote Control

Electrically operated functional equipment on FEB-I may be remotely controlled. This enable an operator to control several autonomously operating FEB-Is.

Remote Operation System – the dashboard

All of the remotely controlled functions may be operated from a dashboard installed on a PC or tablet with access to the internet.

Currently, FEB-I is remotely operated via 3G/4G connection. Other communication with FEB-I may be available upon request.

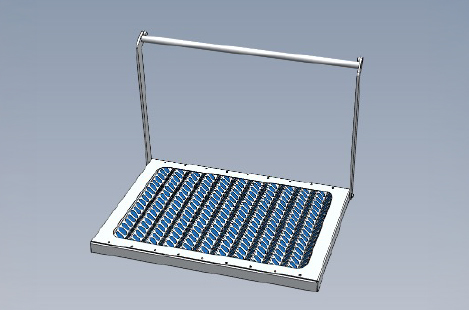

Operating FEB-I with different oil skimmers

FEB-I is designed to operate with virtually any small or medium sized oil skimmers available on the market.

FEB-I can be supplied with a set of flexible mounting rails and plates for mounting of e.g. a hydraulically powered pump unit, as long as the total weight does not exceed 300 kg.

Emptying the FEB

FEB-I is emptied by pumping/skimming the oil from the surface of the oil in the hold. When this happens, the water in the hold will rise and lift the oil from below until all the oil has been skimmed from the surface.

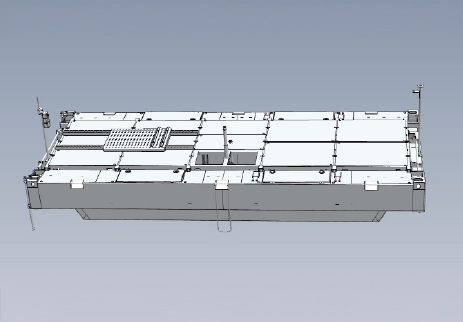

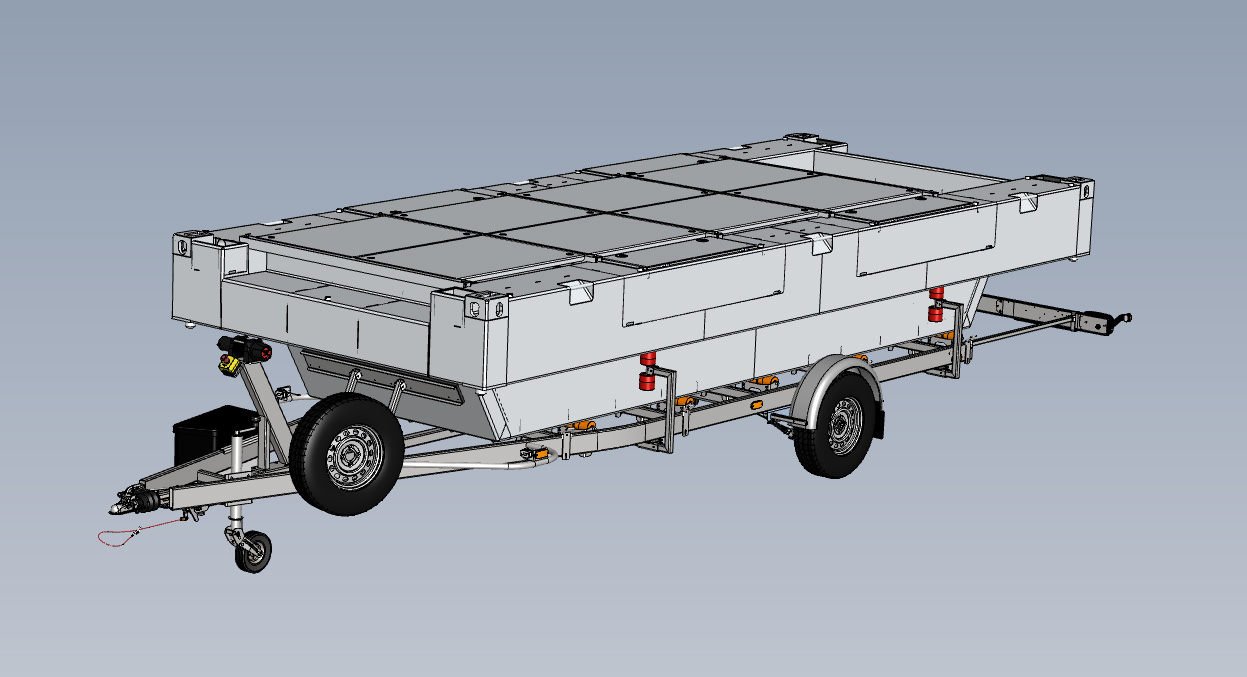

Trailer for the FEB-I

FLEX-FEB has designed a trailer for the FEB-I, which enables easy storage and rapid mobilization and deployment in the event of an oil spill scenario.

The trailer has a payload of 1,400 kg and a total weight of 1,800 kg, which allows for towing with a regular medium-sized car.

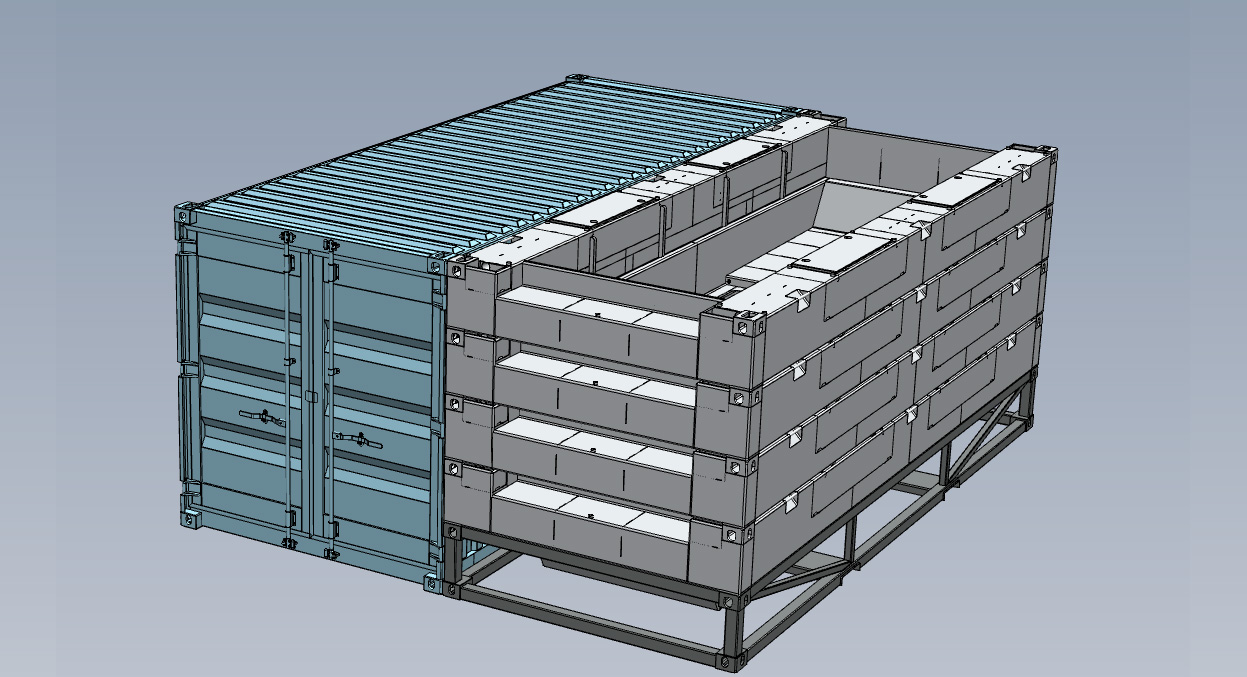

Cradle for the FEB-I

Compliance with the 20′ container format and the possibility of stacking several FEB-I on top of each other, has the advantage that 4 FEB-I units stacked in a transport cradle have exactly the same dimensions as a 20′ container (TEU format).

The cradle and FEB-I units can thus be transported and handled anywhere in the world with already available equipment – so no need for special handling equipment!